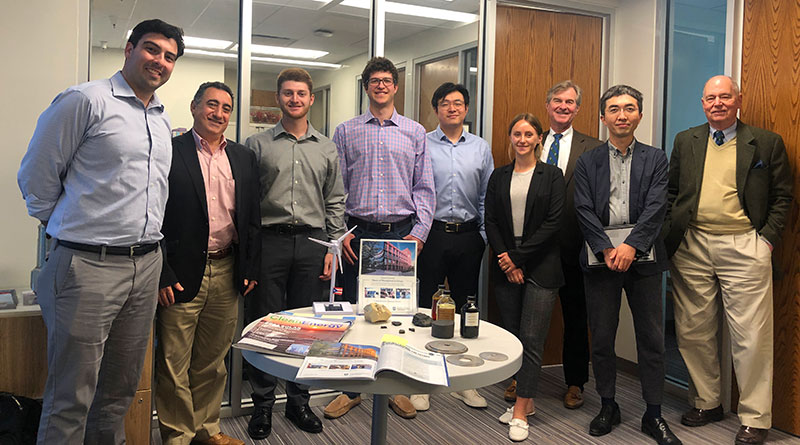

Fluence Analytics President Alex Reed, center, talks to the student team as CEO Jay Manouchehri, standing right, looks on.

Humans produce more than 440 million tons of plastic annually, and much of that production ends up in landfills. A new company hopes to help solve that problem, and to do that, they teamed up with a surprising partner: The Tulane Energy Institute.

Fluence Analytics is a Tulane University spin-out that specializes in continuous analytics and process control solutions for the polymer and biopharmaceutical industries. Ranked by CB Insights as one of the world’s most promising advanced manufacturing startups, the company recently began developing new ways to use its propriety technologies to improve the efficiency of chemical recycling, an alternative to mechanical recycling that breaks down waste plastic and converts it into virgin-like feedstock. While mechanical recycling can’t compete with the staggering volume of waste plastic, chemical recycling has the potential to create a circular economy in which plastic products flow from producer to consumer and back in a continuous cycle.

The challenge is the chemistry. Breaking down plastic waste is a highly volatile process that requires constant monitoring and time-consuming laboratory testing. Fluence Analytics’ automated manufacturing system ACOMP — short for Automatic Continuous Online Monitoring of Polymerizations — will enable plastics recyclers to conduct real-time testing and monitoring of the depolymerization process, resulting in a much more efficient — and much more cost effective — conversion of waste plastic to reusable feedstock.

To help commercialize the system, Alex Reed (SLA ’09), president and co-founder, and Jay Manouchehri (E ’85, E ’87), CEO, reached out to Pierre Conner, professor of practice and executive director of the Tulane Energy Institute.

“Plastics and the circular economy might not capture your attention as an energy project, but plastics are obviously a downstream product from the production of hydrocarbons and this is a project that involves sustainability, which is also what we’re doing here,” says Conner. “It’s a great example of the nexus of energy economics, markets and policy, and the future of a circular economy. It’s just the kind of thing we should be working on at the Tulane Energy Institute as we prepare energy business students for careers into the 2050s and beyond.”

Conner and Eric Smith, professor of practice and associate director of the institute, connected Reed and Manouchehri with their students in Energy Projects, a hands-on course that puts students to work on energy-related projects for real companies. Over the course of the semester, the students learned the technology, evaluated the chemical recycling market, researched peers and ultimately identified potential customers for Fluence Analytics using a matrix to rank firms based on their likelihood of benefiting from the technology.

Libby Antonneau (BSM ’23), a double major in business and environmental studies, initially expected to be working on a renewable energy project, but she soon realized the connection between petrochemicals and the environment.

“The plastics industry has a huge impact on the environment, and how that’s going to change is going to have a huge impact on the energy industry, because plastic is obviously a petroleum-based product,” says Antonneau. “Creating a world where we’re not going to have to use virgin petroleum products to create plastics anymore will have a huge impact on the petroleum industry.”

Reed says he was thrilled with the results of the project.

From left to right, Fluence Analytics’ Alex Reed and Jay Manouchehri, energy students Maxwell Landy, Zachary Clay, Yuanhe Xiao and Libby Antonneau, TEI’s Pierre Conner, Diamond Edge Ventures’ Dr. Naoki Obata and TEI’s Eric Smith.

“We were impressed with the work of the student team, and it set us up to make some key strategic decisions for the direction of our technology and target markets,” he says.

Conner says the Fluence Analytics project is an example of a new type of pedagogy he hopes to bring more of to the energy program: project based learning. In project-based learning, students interact with a company on a specific project over the course of a semester or part of a semester, producing a deliverable at the end.

“Project-based learning is very important in particular for energy because of the rapid pace of change,” Conner says. “This project was cutting edge — it’s not going to be in a textbook and it’s not going to be a case because it’s still emerging. It exposed students to the breadth of the kind of business analysis that needs to be done to progress energy transition and the circular economy, and it turned out like a lot of projects that occur in

real life: There isn’t necessarily one solution.”

The value of project-based learning also appealed to Manouchehri, who worked on similar projects when he was an engineering student at Tulane.

“One of my industry-sponsored projects set me up for my entire career in digital transformation in the process industries,” says Manouchehri. “Coming full circle and working with students experiencing the same journey has been fantastic. These projects really are a win-win for the students and the sponsors while helping the next generation of leaders get some hands-on experience.”

Conner says Freeman, with its longtime focus on experiential learning, is a perfect match for project-based learning.

“Project-based learning is a subset of experiential learning,” Conner says. “It’s a pedagogy that leads students from reading or listening to actually doing. Dean Goes is very committed to experiential learning and wants to grow this within Tulane, and given the fact that Louisiana is at the epicenter of the energy transition — there’s going to be a lot of capital expended here — I think there are a lot of opportunities for project-based learning in energy.”

Conner adds he’s always looking for potential projects for students to work on. Alumni interested in working with students on energy projects should contact Conner at pconner@tulane.edu for more information.